About the Trust

Work on the overhaul of 5025 began at the beginning of 2012. This was thanks to grants or promises of support from the Strathspey Railway Company, the Strathspey Railway Trust, the Heritage Lottery Fund the Strathspey Railway Association and the significant amount which had already been raised from our supporters though appeals.

Major progress has been made on the locomotive and tender frames, axleboxes, motion, dragboxes and valve gear at Aviemore and on the major rebuild of the boiler, reprofiling of the tyres of the locomotive and tender wheels and construction of a new tender tank at Riley Engineering of Bury. Work has also included the casting and machining of a pair of new cylinders

The WEC Watkinson Trust originally hoped to return 5025 to service in 2015, however owing to the amount of work needed, we now hope that the engine will be ready towards the end of the 2019 season. ( see edit below)

We are still on track for 2019 to be the year in which the oldest and best example of a L.M.S. Black Five steams again. Due to a very tight budget the original intention was to return 5025 to traffic by carrying out the minimum necessary work. However, she is an iconic locomotive and quite early on the sensible decision was taken to restore her to “as new” condition. This has resulted in considerable extra work and expense and has left the Watkinson Trust desperate for funds.

Edit, we were heavily delayed waiting for the boiler, this has put the completion date back to around summer 2020.

Further edit, owing to covid lockdown, this has been further delayed, completion date is now summer 2021.

The original budget of £354,050 has been spent wisely and with care. However, additional boiler work has cost a further £39,345, new cylinders and frame repairs £33,350, and other work such as a new cab, injectors and super heaters upwards of £22,500.

Although most of the work now being carried out is labour intensive, certain costly goods and services are essential to finishing the job and it is only with your help that we can make it happen.

We still need to complete the tender tank and the under frame, produce boiler cladding, purchase copper pipe and various fixings and fastenings and pay for transport, crane hire and specialist machining.

The Watkinson Trust would like to thank you for any generous donation you are able to make towards a successful conclusion.

Please use the “Donate” facility below to support this worthwhile project through Paypal.

Friday, 21 July 2017

The Boiler

The boiler for 5025 is being refurbished by Riley's engineering. Here are some pictures from a recent visit to view the progress.

The first view is looking at the firebox back plate, this has been renewed some three quarters of the way up.

Moving to the side we can see one of the shoulder patches where material has been cut out to eliminate cracks.

The lower side of the firebox has also been renewed.

This view of the front of the firebox shows the new throat plate.

Another close up view of the same area.

Another view of the firebox side plate renewal.

This view also shows the new front section of the boiler barrel.

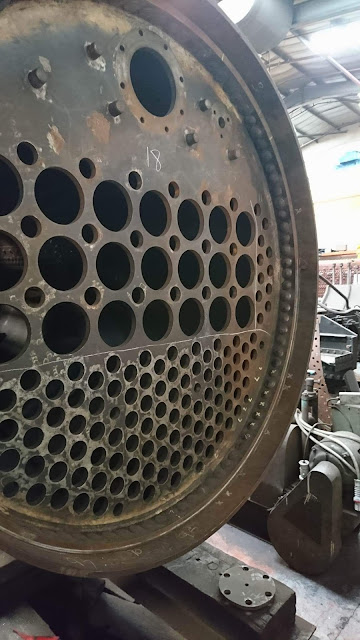

A view of the front of the boiler showing the new front tube plate.

Saturday, 8 July 2017

Update 8th July 2017

Progress, the job comes along slowly. Much depends on when a group of at least four are available for the riveting.

Looking down from above, the rear drag box is now completely riveted into place.

A view from the floor level.

And from underneath, the steam brake has been fitted to its bracket.

Back up to the top where the refurbished reverser has been fitted.

A view across the top of the frames, in the background the lubricators have been refitted.

A view of the lubricators from floor level.

Looking up from underneath, the new running plate has been riveted into its place.

A view from above showing the new running plate. The right hand plate has been riveted into place, whilst the left has just been bolted on and awaits riveting.

A view from the same position looking towards the rear.

At the front, the smoke box saddle has been lowered into place. The holes into the front and rear stretchers have been drilled and at this stage should have just needed lifting out to clear the drilling swarf. However it will need further attention before this can happen. During the repair of this item, the sides have distorted, causing the frames to pull inwards when it is bolted into place. It will need shimming and further machining.

Another view.

Four extra holes will be drilled through the frames and into the saddle, these are marked in the centre, between the exhaust port holes. This is the area where water has got between the frame and the saddle, allowing corrosion to force the two apart. On later engines, studs were fitted to the back of the cylinders which pulled this area together. On 5025 these will be rivets.

The next area to receive attention was the running plate brackets on the left hand side of the cab.

Looking down from above, the rear drag box is now completely riveted into place.

A view from the floor level.

And from underneath, the steam brake has been fitted to its bracket.

Back up to the top where the refurbished reverser has been fitted.

A view across the top of the frames, in the background the lubricators have been refitted.

A view of the lubricators from floor level.

Looking up from underneath, the new running plate has been riveted into its place.

A view from above showing the new running plate. The right hand plate has been riveted into place, whilst the left has just been bolted on and awaits riveting.

A view from the same position looking towards the rear.

At the front, the smoke box saddle has been lowered into place. The holes into the front and rear stretchers have been drilled and at this stage should have just needed lifting out to clear the drilling swarf. However it will need further attention before this can happen. During the repair of this item, the sides have distorted, causing the frames to pull inwards when it is bolted into place. It will need shimming and further machining.

Another view.

Four extra holes will be drilled through the frames and into the saddle, these are marked in the centre, between the exhaust port holes. This is the area where water has got between the frame and the saddle, allowing corrosion to force the two apart. On later engines, studs were fitted to the back of the cylinders which pulled this area together. On 5025 these will be rivets.

The next area to receive attention was the running plate brackets on the left hand side of the cab.

Subscribe to:

Comments (Atom)